-

Ordinary Products

Look at the detailed products

of Geumgang Mobile-Rack. -

Gallery

These are the supply cases of

Geumgang Mobile-Rack. -

Customer

Geumgang Mobile-Rack is

always doing its best to

realize customer value.

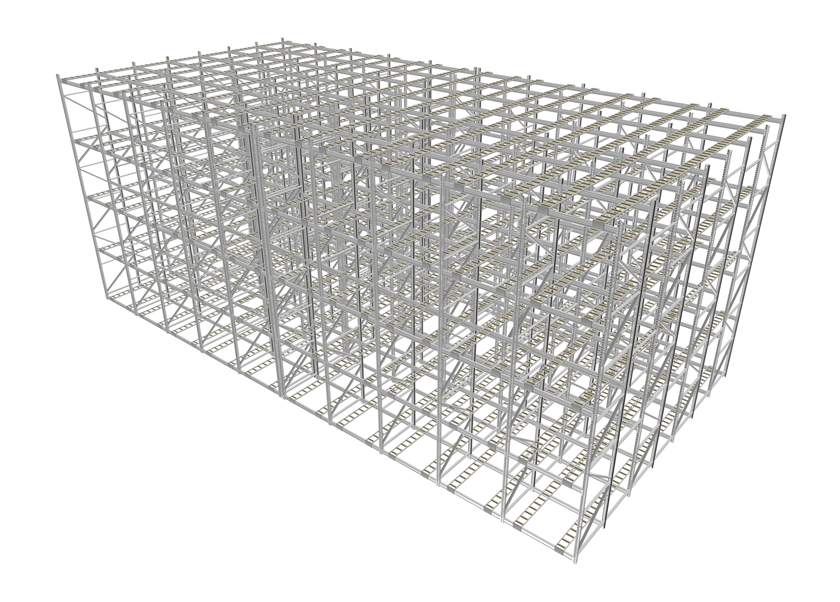

Ordinary Products

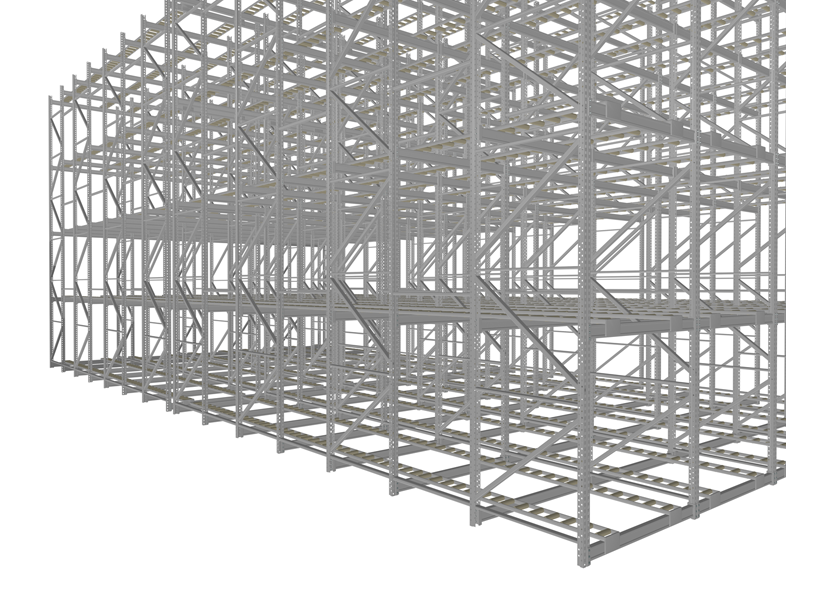

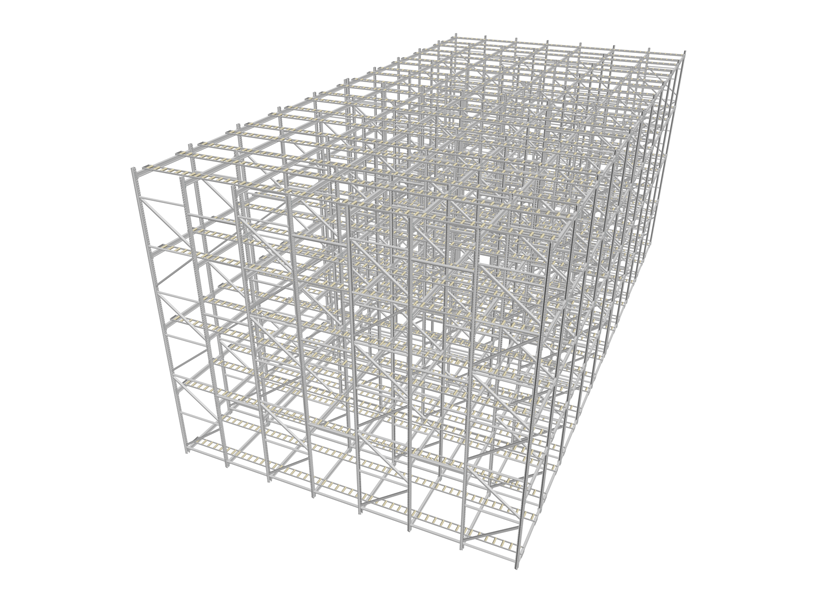

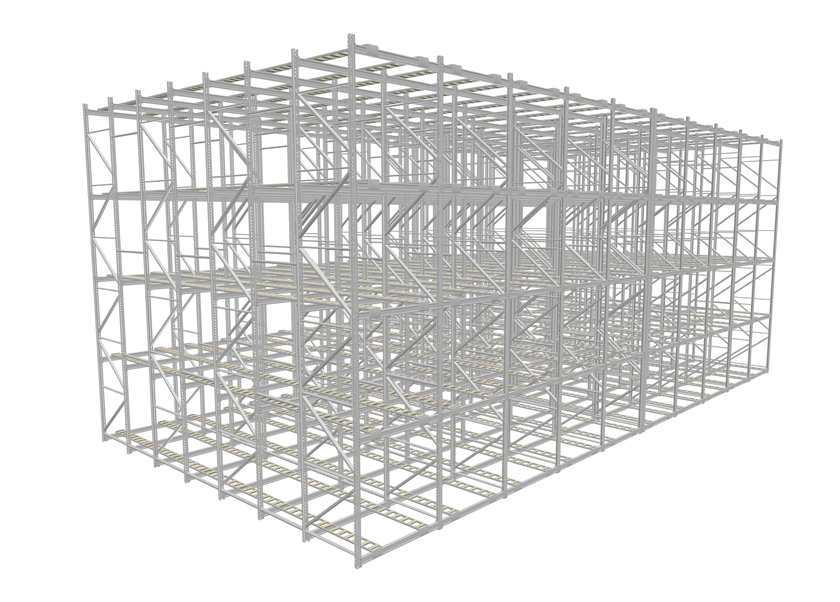

Rack System

Sliding Rack

The sliding rack is equipped with a roller conveyor with appropriate tilt from the receiving side to the delivering side by connecting the cantilever on the left and right sides of the drive rack.

In this method, the stock is moved to the outlet side in sequence, so that the first-in / first-out method is completely carried out.

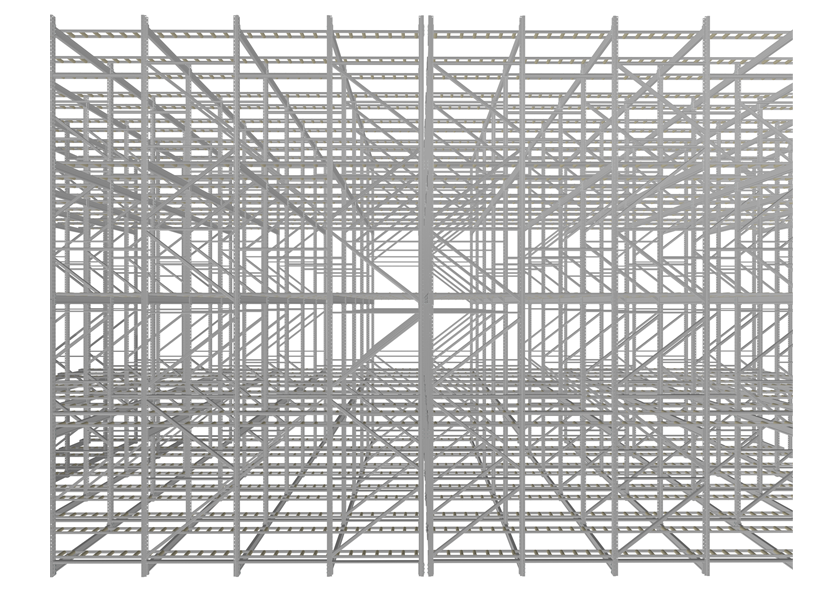

Characteristic

- • The best design and choice of conveyor would be decided by the cargo’s shape and weight and driving mileage. The optimum angle is 3˚~4˚ and speed is 10~15m/min.

- • The stopping and going astry of cargos would be stopped by the conveyor made with unique design and metal runners attached to the back of pallet.

- • The entry guide should be installed to ensure that cargos arrive correctly on the conveyor.

- • The stopper on the delivering side should be installed for absorbing shocks when cargos stop.

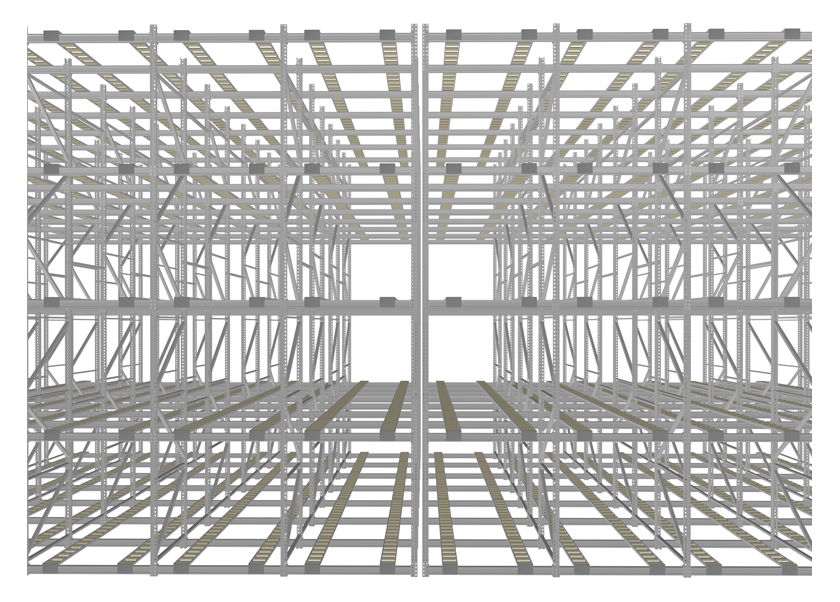

Attentions

- • When using pallets, connecting parts of the roller conveyors should be metal.

- • Cargos should be banded well as they are likely to damaged by the movement after pallet loading.

- • It is not suitable for various kinds of product and small quantity storage.

- • Perfect designing is required due to the weight of the cargo, there are restrictions on the slope and the speed.

- • Cargos cannot be carried out in the middle of racks.

- • The depth of the racks can be up to 30m even it is various depending on the storage capacity, the shape of the ground, the cargo volume, and the situation, etc.

- • The use of dehumidifiers in the warehouse is necessary to prevent conveyors from sweating.